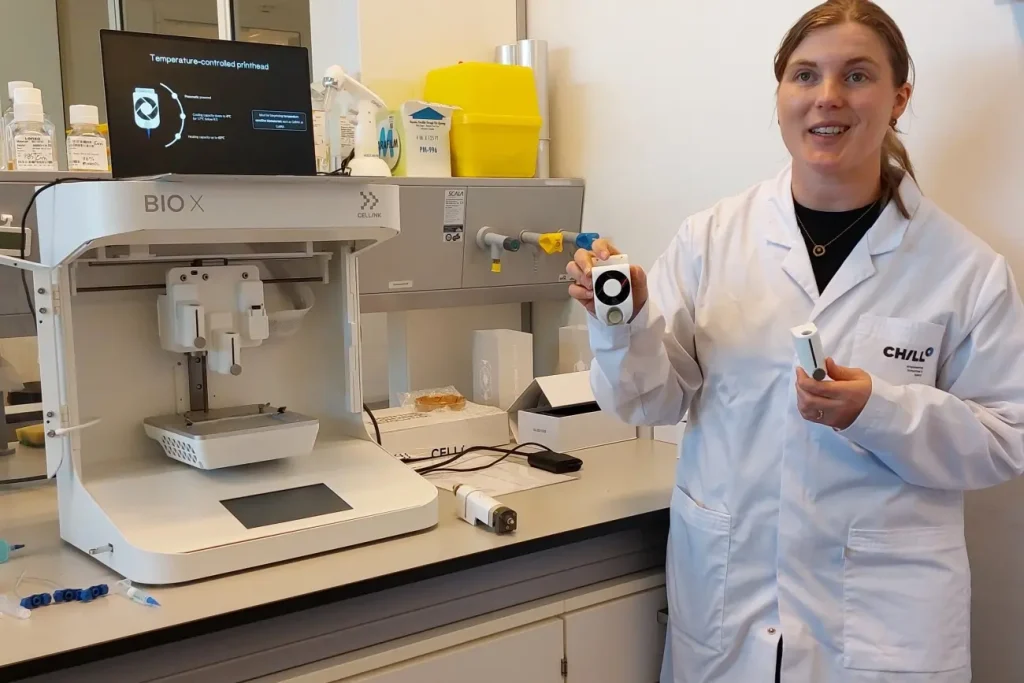

The Material Sciences research group at Zuyd and partner organization CHILL, based at Brightlands Chemelot Campus, have recently acquired an advanced bioprinter, capable of printing biological cells and tissues in model form. This technology enables small-scale experimentation with 3D structures and tissue compositions — even to the point of printing a piece of steak.

According to Olaf Brouwers, senior lecturer-researcher at the Academy of Applied Science, bioprinting offers valuable insights for future applications in both medical innovations and sustainable food production.

“The BioX 3D Bioprinter is used within the Academy of Applied Science for research into innovative applications in both medical and food technology”, says Olaf. “With this bioprinter, students and researchers can work on concrete applications in both domains. Bioprinting is not a goal in itself, but a powerful tool within a broader ambition for sustainability and innovation.

An alternative to animal testing

In the medical sector, bioprinting offers opportunities to more accurately mimic human tissues under laboratory conditions. This can help reduce animal testing and provide scientists with better insights into diseases using human cell models. Applications include the development of advanced in-vitro models for conditions such as cardiovascular diseases or bone growth.

“We focus on the research phase, but in the long term, bioprinting could also contribute to the development of implants or even functional tissue for transplants”, says Olaf. “It’s not about directly ‘printing organs’, but about creating building blocks for regenerative medicine.”

Cultivated meat as a future perspective

Beyond the medical world, bioprinting also plays a significant role in the emerging field of cellular agriculture. In this field, animal products — like meat — are produced without the need to slaughter animals. The required cells are grown in a controlled environment and then structured using a bioprinter, for example into a piece of muscle tissue that closely resembles steak. Cultivated meat generally requires less land, water, and energy than traditional livestock farming and helps reduce animal suffering. It also offers a perspective for more sustainable food production, with fewer risks of antibiotic resistance and no need for hormone use.

Olaf Brouwers, senior lecturer-researcher at the Academy of Applied Science Zuyd Hogeschool: “Through our partners, we have access to a broad network of companies and research institutions. They help accelerate innovation in research and education around cultivated meat and cell technology. Thanks to this bioprinter, many more collaborative projects will emerge in the future.”