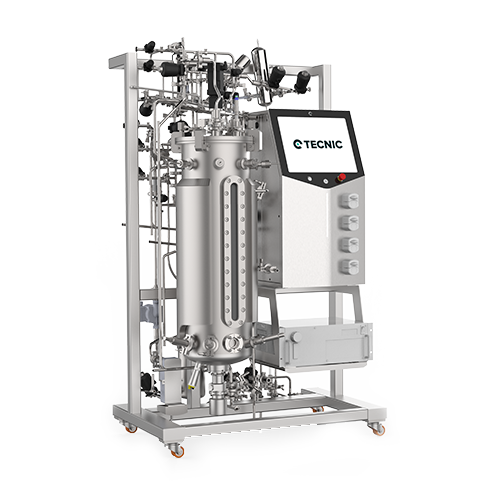

With replaceable vessels and working volumes of 10, 20, 30, and 50L, these bioreactors offer maximum efficiency and flexibility to take your research to the next level.

Its replaceable vessels make cleaning and maintenance easy, and the system is designed to minimize contamination risk. Furthermore, the system’s versatility can extend to applications such as a plant bioreactor, allowing a wide range of research possibilities.

Achieve precise weight control with the Load cell

The peristaltic pumps feature a 2 in 1 concept with multi-way pumps that are adjustable and can even function as fixed pumps. The system also includes an auto sterilization feature with a steam self-generation system for SIP. TECNIC has designed special additional valves and a large sight glass for easy monitoring and control.

Weight and dimensions

The ePILOT® Bioreactor approximately measures 1095 mm in length, 650 mm in width, and 1855 mm in height. There are four different vessels which their system weight approx and working volumes:

- 10L Vessel: 300 (microbial) | 290 (cellular) kg with a working volume of 1.5 | 2 to 10L

- 20L Vessel: 325 (microbial) | 300 (cellular) kg with a working volume of 2.3 | 3.5 to 20L

- 30L Vessel: 350 (microbial) | 310 (cellular) kg with a working volume of 3.6 | 5.5 to 30L

- 50L Vessel: 400 (microbial) | 325 (cellular) kg with a working volume of 5 | 8.4 to 50L