Traditional Cell culturing methods have remained relatively unchanged for decades. They relied on manual processes, requiring significant time and effort from scientists and technicians. As your cells require a lot of special attention, automation and standardization of these workflows have not been the focuspoint of many research labs. However, when optimizing your cell culture method and working to scale-up your workflow, the difference in quality of work on your cells between technicians can cause unnecessary variations, and many replicates after replicate is needed to prove the efficacy of your methods.

The Microplate Agitation System C.NEST from CYTENA revolutionizes the cell culture workflow by ensuring standardized and tightly controlled culturing conditions. This system not only enhances reproducibility but also improves cell growth and viability by gently homogenizing the culture medium in 96- and 24-well plates.

- Eliminate technician-dependent variability → Reduce the need for repeated replicates.

- Achieve unmatched control over optimal conditions → Shorten culture times when scaling up.

- Run up to 16 different configurations simultaneously → Conduct multiple studies in parallel.

By integrating semi-automation into your cell culture workflow, you can streamline processes, improve efficiency, and achieve more reliable results.

How C.NEST enhances your cell culture workflow

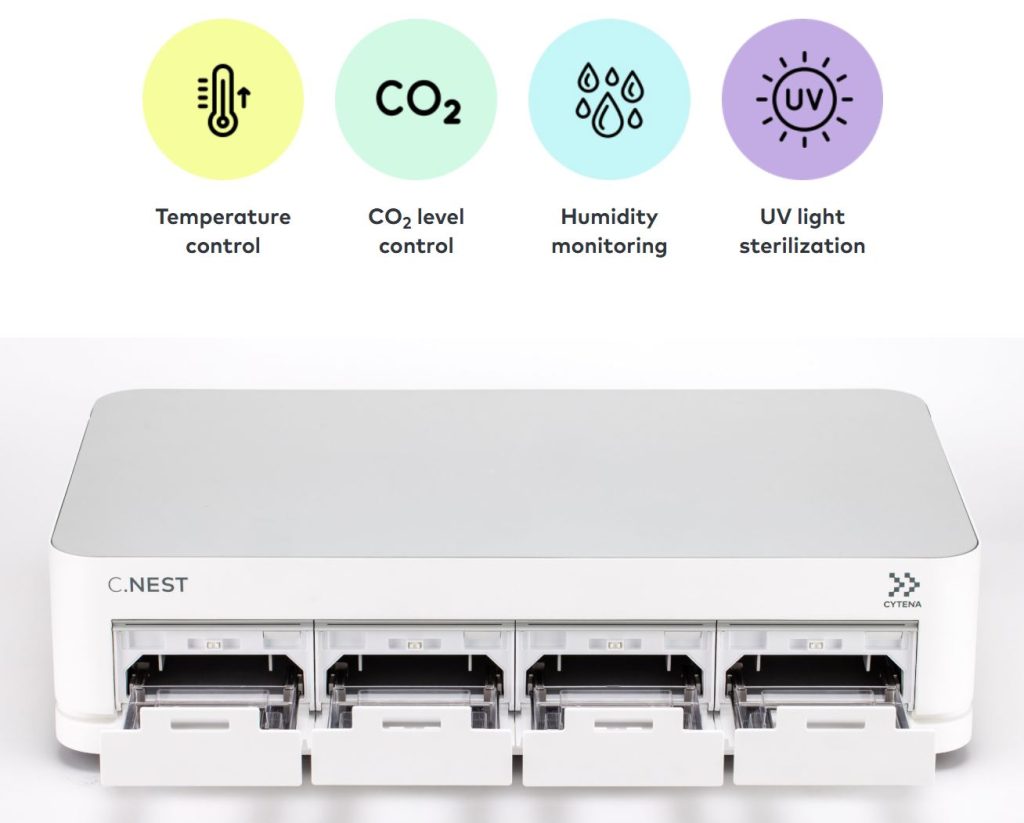

CYTENA C.NEST combines their patented and highly gentle medium agitation technology, applicable in 96-well and 24-well plates, with the flexibility to scale up from 4 to 16 separate incubation chambers. Each with its own temperature, CO2 and optimal mixing settings. Sterility is guaranteed by the use of filtered air and a UV-decontamination for each chamber.

To maintain sterility, each chamber is equipped with filtered air and UV-decontamination, ensuring a contamination-free environment. With C.NEST, you can consolidate multiple experiments within a single, compact system.

Imagine using one system for:

- Mammalian suspension cells

- Bacterial and fungal cultures

- Organoid / spheroids

- Immunoassay (ELISA) incubation

These have their own special needs, but controlled within one user-friendly interface. And best of all: No more large and clumsy incubators that take up valuable space, require frequent maintenance, and are repeatedly exposed to environmental fluctuations as technicians open and close them throughout the day.

How does Automation fit in your cell culture workflow?

How about a sterile working environment that fits on you lab bench, right next to the C.NEST incubators, that does the pipetting for you?

The Opentrons FLEX offers an accessible and affordable solution to take the most time consuming pipetting tasks off your hands:

- Media exchange Especially when working with microplate cultures, media exchange is a perfect task for a versatile and easy to program liquid handler like the FLEX

- Cherry-picking The Opentrons FLEX is able to read and process CSV files and automatically perform the laborious task of cherry-picking cellines from a 384 well plate to 96/24 well plate. Gentle pipetting, sterile working conditions and the speed from automation ensures a high quality process.

- (serial) Dilutions High precision and accuracy in pipetting is where automation really shines. When performing serial dilutions, manual pipetting takes up time and effort from mostly highly educated personnel that should have their hands free for less repetitive work.

Combining automation, standardization and flexibility

Imagine a cell culture workflow that boosts quality, efficiency, and throughput, while significantly reducing lab space, energy consumption, and hands-on time. By combining the power of C.NEST and Opentrons FLEX, your lab can seamlessly integrate automation and controlled conditions, ensuring faster, more reproducible results with less manual effort.

The future of cell culture workflow is here—streamlined, standardized, and fully optimized. Are you ready to take the next step?

Conclusion: The new standard in cell culture workflow

In conclusion, by combining the power of improved control and flexibility, unmatched precision and ultimate standardization of your process, hands-off times can be greatly improved. All this while also reducing the use of precious labroom space and energy usage. Most importantly, both your cells and your valuable technicians will be happy.

For more information on how to optimize your research workflow or application, feel free to contact us.

Want to see other workflow possibilities? We’ve got you covered, check our dedicated workflows page