Home » Instruments » ePROD TFF

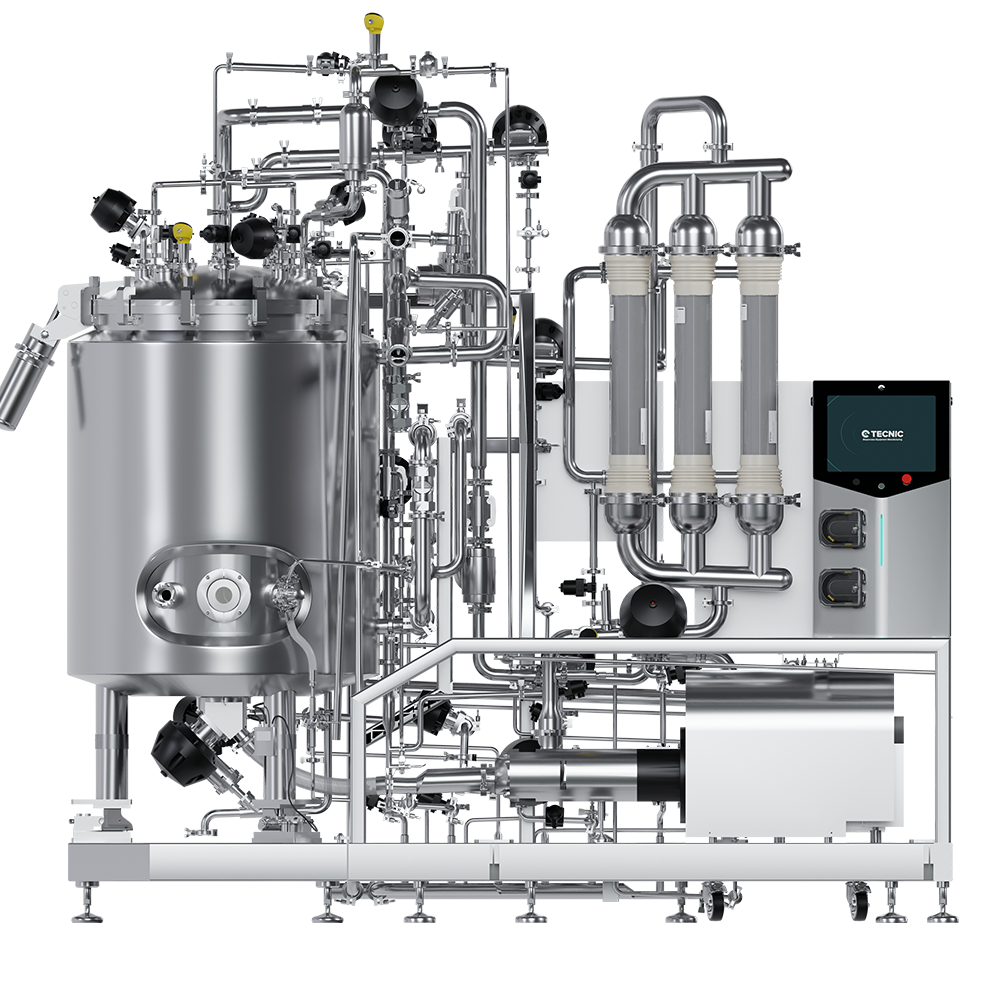

The ePROD TFF system is an advanced, fully automated Tangential Flow Filtration solution designed to optimize downstream production scales for various bioprocessing applications. This cutting-edge equipment is designed to simplify the filtration process and enable you to focus on other aspects of your production, providing reliable and high solute retention for continuous operation.

It includes a magnetic-agitated tank vessel of 500L of working volume and has a maximum filtration surface area ranging from 7 to 65 m², meaning it can handle a wide range of volumes for microfiltration, nanofiltration or ultrafiltration applications. ePROD TFF system is available in a variety of configurations that include cassette, ceramic, and hollow fiber solutions to suit the specific needs of the bioprocess.

The dual control box allows for multi-user registration, offering complete control over the filtration process. This functionality enables the operator to set and monitor the process parameters through a user-friendly interface and the integration of digital sensors that provides real-time data and insights, crucial for maintaining the precision and efficiency of the filtration process.

It also integrates multiple operational modes like Concentration, Diafiltration, Trans Membrane Pressure (TMP) and Cleaning-In-Place (CIP). These features, combined with its precision control modules, ensure optimal performance across various bioprocessing tasks. Finally, the ePROD TFF is designed to meet Good Manufacturing Practice (GMP) guidelines, and its advanced technology makes the bioprocess easy to validate and document.