Home » Instruments » eLAB TFF Single-use

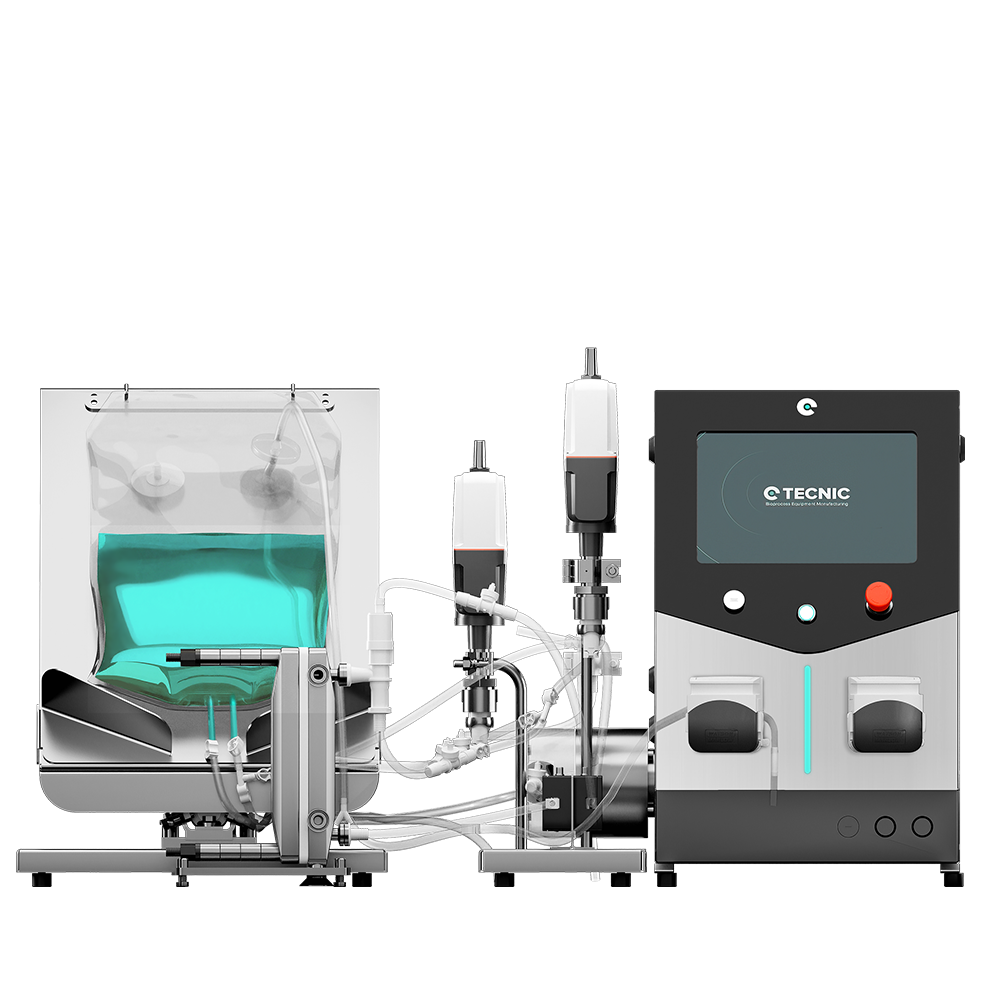

Engineered to meet the rigorous demands of biotechnological downstream processes, the eLAB® TFF SU fully automatic systems stand out with a remarkable filtration performance and ensures unparalleled throughput and efficiency during continuous operation. Furthermore, the Single Use feature of the eLAB® TFF adds a layer of sterility and exceptional convenience, making it an ideal solution for applications where purity and contamination prevention are paramount. The equipment comprises two main modules:

The first is the filtration assembly, which includes a single-use tank with a volume ranging from 2 to 10 liters, housing the product to be filtered, and a filtration membrane with a surface area spanning from 0.1 to 0.7 m². The bag is held in place by a load cell and incorporates a conical bottom to minimize the risk of product losses. This plastic tank is firmly secured with a fixed support and includes the tangential filter for biomolecule purification. Both the filter and the support undergo pre-gamma irradiation to meet rigorous quality standards.

The equipment is seamlessly complemented by the TECNIC tower, equipped with a touchscreen interface, indrustrial PLC, and the eSCADA® software, facilitating equipment interconnection, data traceability, and comprehensive process control. The tower incorporates two peristaltic addition pumps, a USB port for streamlined data extraction, and a LED status indicator for monitoring the equipment’s operational state.

Elevate your bioprocessing capabilities with the precision, sterility, and innovation embodied in the eLAB® TFF system, essential for biotechnology laboratories seeking a straightforward and secure method to uphold sterility and prevent product contamination.