Optimizing bioprocessing outcomes with innovative engineering and precise regulation.

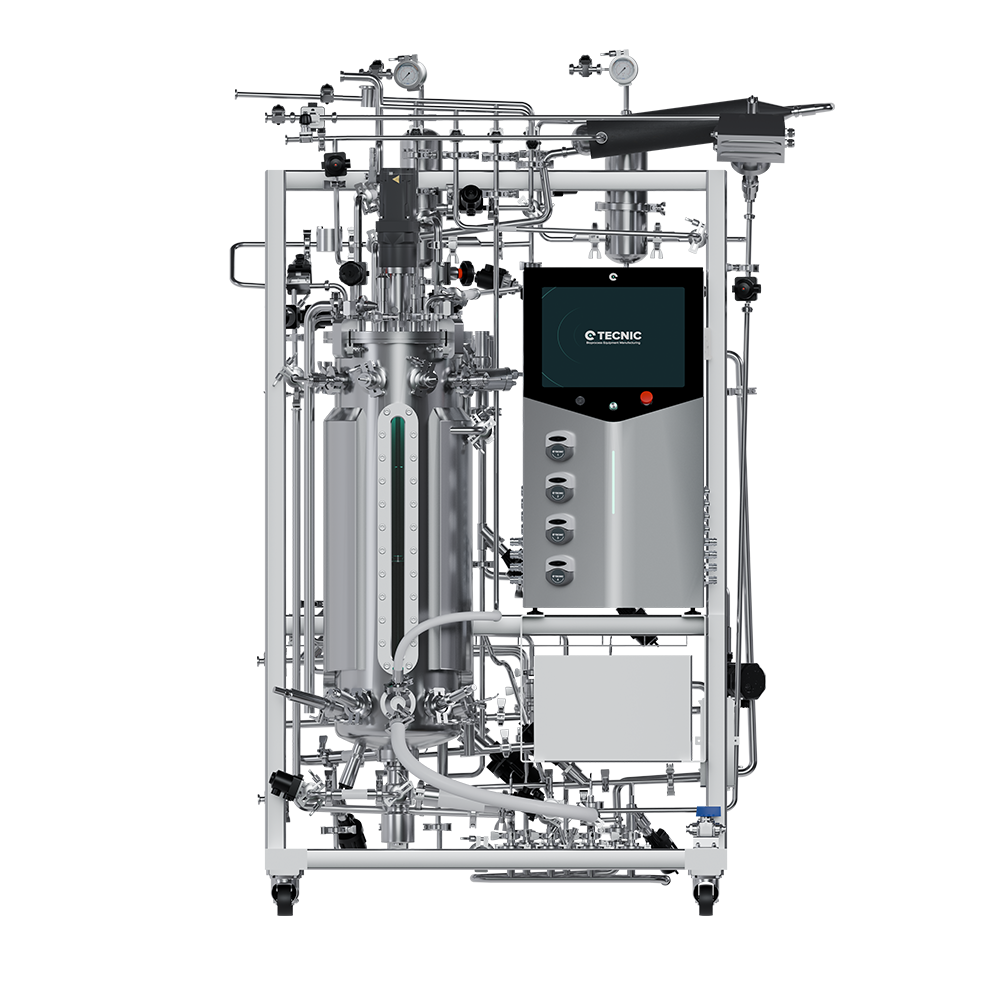

The ePILOT® is made of stainless steel AISI 304 and 316L. It is a crucial tool in upstream processes, providing exceptional productivity in both cell culture and microbial fermentation. Its design, crafted to meet diverse client demands, prioritises efficient culture growth and offers various vessel sizes for seamless scale-up productions.

Integrating a PLC into our bioreactor improves bioprocessing success by providing flexible programming, ensuring a comprehensive understanding of each stage of the process.

Our pilot scale bioreactor features advanced monitoring systems. These systems enable the real-time tracking of crucial parameters like pH, pO2, temperature, and foam levels. This tracking ensures ideal conditions for the growth and development of cells and microorganisms.

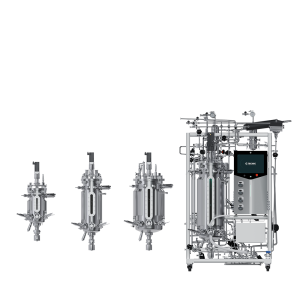

Key strategies for effective scalability in pilot scale bioreactors

With working volumes of 10, 20, 30, and 50 liters, the interchangeable vessels of the ePILOT® facilitate the transition between different scales of production or research, without the need to invest in multiple systems. The bioreactor is dedicated to precision and adaptability, with real-time monitoring through integrated sensors.

Key components include: external jacket, sparger, overlay gas inlets, rupture disc, addition valves, and ports for sensors, sampling kit, a bottom valve and a front-integrated sight glass allows monitoring of crucial parameters like turbidity and agitation.